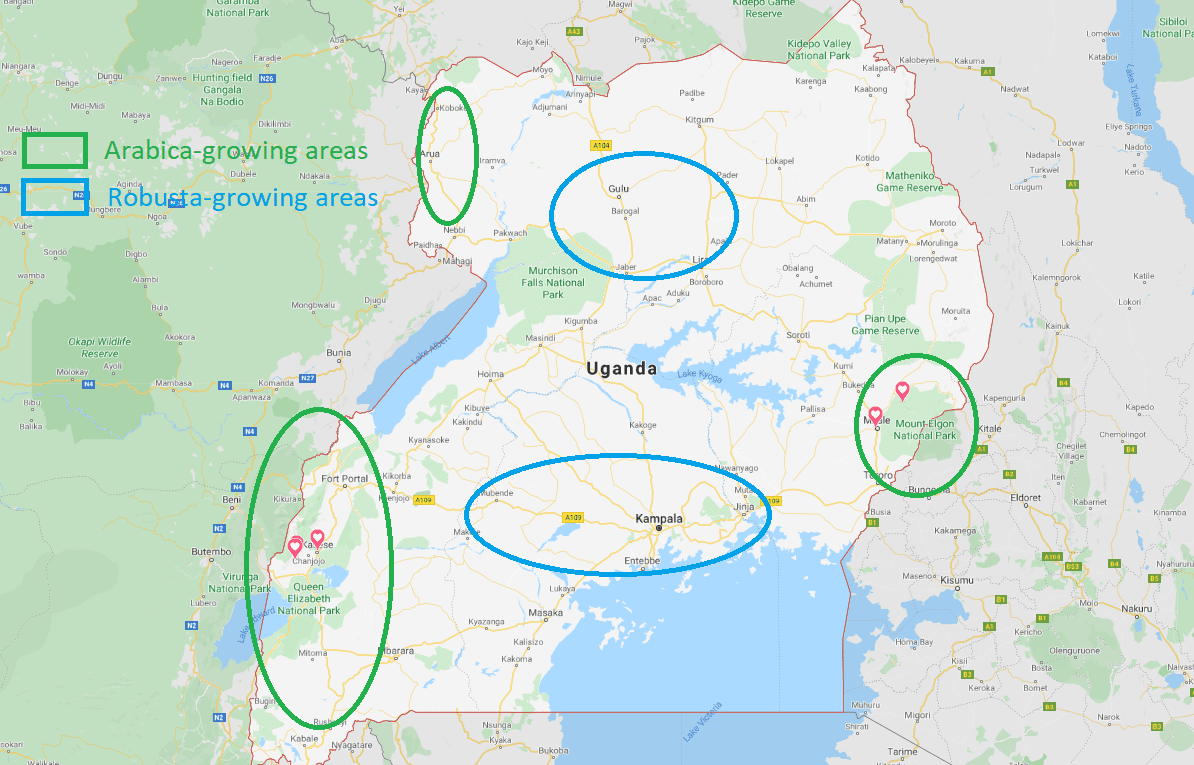

Even though Mt. Elgon Agroforestry Communities Cooperative Enterprise (MEACCE, pronounced mee-ack) officially formed in July 2017, in many ways it has the energy and drive of a younger startup. While Uganda produces 2.3% of the world’s total coffee supply, around 80% of the country’s coffee production is Robusta grown in the central and northern lowlands. Uganda’s washed Arabica coffee, better known in the specialty coffee realm, is mainly produced in the southwest (Kasese area), the northwest (West Nile region), and in the east near Mt. Elgon.

At 4,321 meters, Mt. Elgon is a sprawling territory with plenty of space for numerous cooperatives and coffee collection centers. Mbale town is the area’s commercial center and home to most of Mt. Elgon’s dry mills and coffee warehouses. In terms of coffee production, Mt. Elgon is divided between the higher altitude northern region and lower altitude southern region.

During my 2-day visit I spent 18 discussion-, laughter-, and roasted-banana-filled hours in the car with Luke Wepukhulu (MEACCE’S Director of Operations) which gave him ample time to fill me in on the details of MEACCE’S history. MEACCE developed in July 2017 from the remnants of an older, poorly-run cooperative. Understandably hurt and shaken by the cooperative’s collapse, the farmer members made significant changes when forming MEACCE. Not wanting to be “the same beer in a different bottle,” the founding members prioritized sharing of information about finances, trainings, and governance among their peers. They strategically partnered with an exporter from the get-go, and MEACCE produced 7 containers in the 2017-2018 season, far exceeding even their own expectations.

In 2019 MEACCE parted ways with their original exporter and have overcome several obstacles in order to become the cooperative they are today. In the second half of 2019 they secured financing from a social lender, completed certification paperwork, secured a space to rent for their warehouse storage, found a third-party dry miller, obtained an export license and, last but not least, secured several contracts with buyers. In addition, heavy unseasonable rains in December significantly delayed the harvest which allowed them time to receive financing before beginning to collect parchment.

MEACCE has 2,433 members (600 women) with 11 primary society cooperatives under its umbrella cooperative. MEACCE’s team is lean, with 11 staff members, a rented facility, and enough passion and drive to fill a stadium. Most members have around 600 coffee trees on backyard plots and are currently depulping and washing on their farm with the plan of having more centralized processing facilities in the coming years.

Only a small number of farmers own their own depulpers, and those with equipment allow other members to use the pulpers for a small fee. After floating cherries in a bucket and removing the floaters, they depulp and dry ferment in buckets or poly sacks for 24-48 hours. After fermentation they bucket wash the parchment, then dry it on raised beds or tarps for 3-4 weeks before delivering to the primary society’s storehouse. At the primary society, staff take a moisture meter reading, hull a sample and sort for defects. The parchment is then delivered 2-3 times/week to MEACCE’s main store in Mbeya where it is again measured for moisture and defects by John, MEACCE’s QC Manager. If the parchment doesn’t meet MEACCE’s quality standards MEACCE provides a space for additional drying and sorting on the premises.

In storage, the parchment is kept separate by primary society and each ~70kg bag of parchment is labeled by date, primary society name, lot and bag number. Once MEACCE has enough parchment for a container’s worth of green coffee they will send it to a third-party miller to be milled and graded. MEACCE will then hand-sort before the coffee is bagged and sealed for export to Mombasa, Kenya.

I had so much quality time with Luke that I took notes of some of my favorite Luke quotes:

“We want to create a difference, pass on value to farmers. Once a farmer appreciates his or her value as a member of the cooperative, and receive second payments and Fair Trade premiums, then he or she will be even more motivated to comply with our requirements of quality…In our meetings now, many farmers are speaking, questioning, and sharing their thoughts, instead of just one or two.”

“Things are happening. We are getting our farmers involved in decision making, teaching board members and (farmer) members about how pricing is determined, teaching about the idea of ‘export selling’ (if farmers delivery cherry and parchment on credit, and wait on payment until the cooperative is paid by the importer, the farmer will not only receive more, but the cooperative will have to borrow less from the bank, allowing them to invest more capital back into the cooperative).”

“When a farmer has pruned his trees well and he sees all of the flowers on his cherry trees, he [or she] will say, ‘My bank account is smiling today…today my bank account is doing well!’"

Of course MEACCE faces challenges like many other groups. Coffee berry disease and coffee white stem borer are perennial plant problems, and climate change has increased danger from a more extreme flood/drought cycle, and even hailstorms which can be very damaging to coffee. Currently many members do not have enough funding to construct raised beds or own their own pulpers.

As an umbrella cooperative, MEACCE is eager to build a small lab and learn about sample roasting and cupping in order to better support advise their members. With time farmers are rebuilding trust in the cooperative structure, understanding that progress takes perseverance. They’re focused on good agricultural practices including maintenance of trenches for water conservation, pits for organic composting, stumping trees every 5-8 years to maximize productivity. Each primary society cooperatives includes multiple 20-30 member farmer groups where they establish microfinance partnerships and implement farmer field schools to share information.

As Atlas facilitates the import of MEACCE’s first container of coffee under their new export license, we’re eager to see where the future leads for them!